Riverside passionately upholds the ideology of Feel, Imagine, Do, Share, and this vision finds its ultimate embodiment in the Maker-Verse, a dedicated space for this purpose.

Welcome to the Maker-Verse, and get ready for the ultimate skill-building adventure! We've got Hand tools, Power tools, Resources, and Machines – it's like a toolbox of the future! We're all about turning your crazy cool ideas into real things you can touch and use. Imagine being a superhero inventor, bringing your dreams to life! And the best part? You're not just fixing problems, you're becoming a full-on innovation wizard.

This initiative is all about getting your hands on cool tools and materials – it's like crafting magic. You'll become a skills wizard with your very own projects, and guess what? You'll have a secret weapon for the crazy fast evolving world out there. So, buckle up – you're in for a skill-tastic ride that'll take you to the stars!

Muzammil sir is the ultimate makerspace champ – he practically brought the whole concept to life! He's the captain of the makerspace ship, steering the course, making sure all those awesome ideas come to life. He's like the chief of fun, always finding new ways to get students excited and making the most out of the space. Total makerspace superhero, if you ask me!

Our makerspace currently has the following equipment which will allow students to learn programming, build robots, learn how electronics & sensors work.

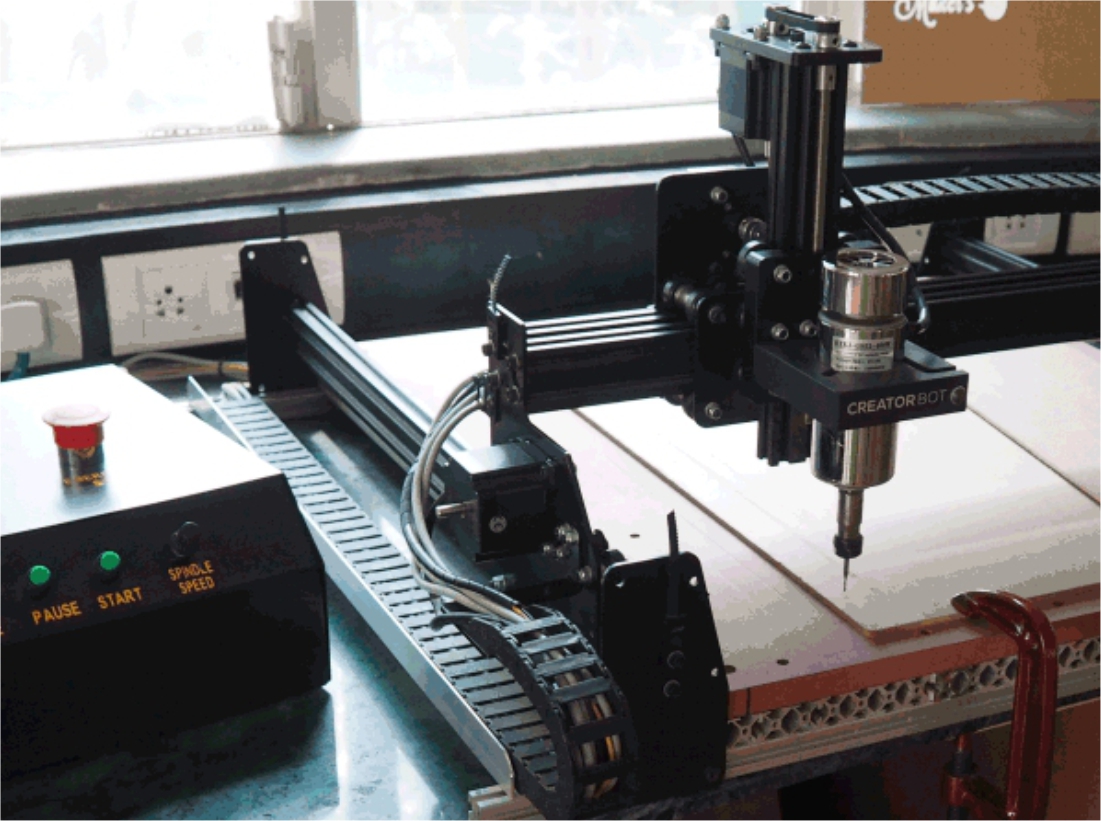

The CNC router at the school can work with metal, plywood, wood, among other hard materials. Controlled by a computer where students create & upload their designs, the CNC mill can then precisely cut the material.

READ MORE

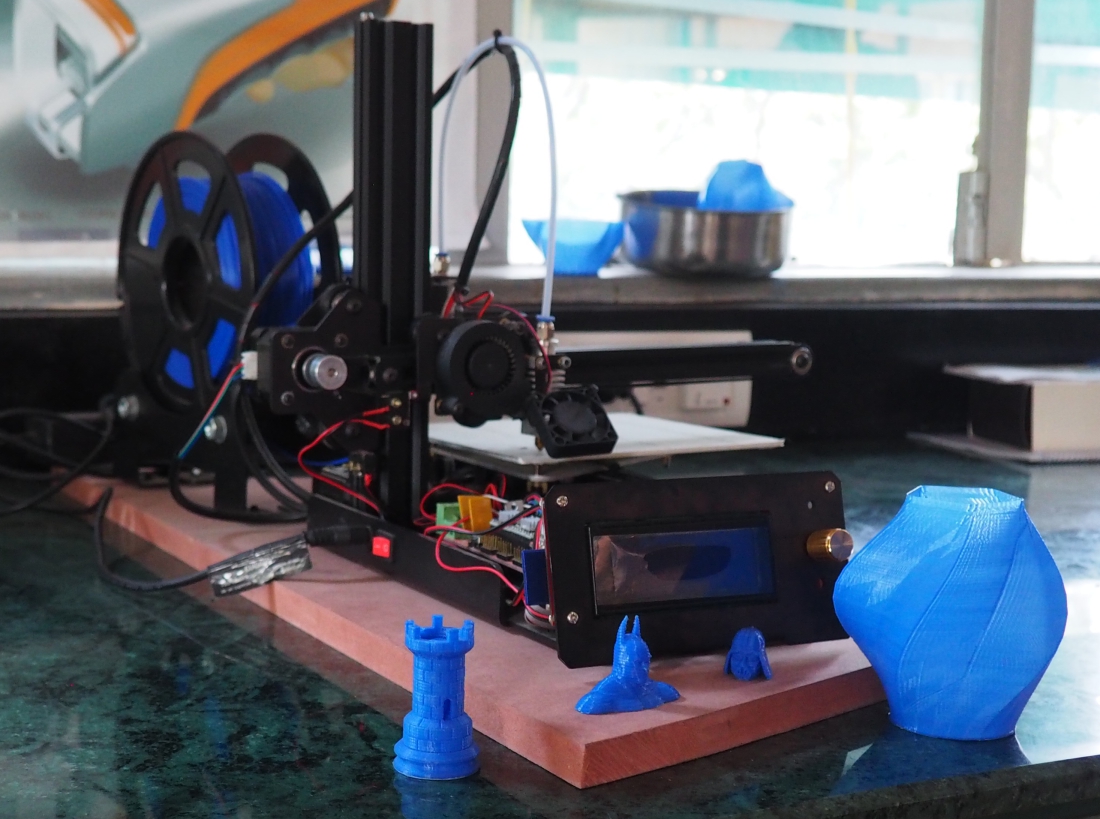

The 3D-laser printer uses a plastic (poly-lactic acid; PLA) which is heated and then precisely printed (with a precision of 0.4 cm) to create complex 3-D shapes. One of the most exciting production technologies in the world, 3D printing technology has already started revolutionizing global manufacturing.

READ MORE

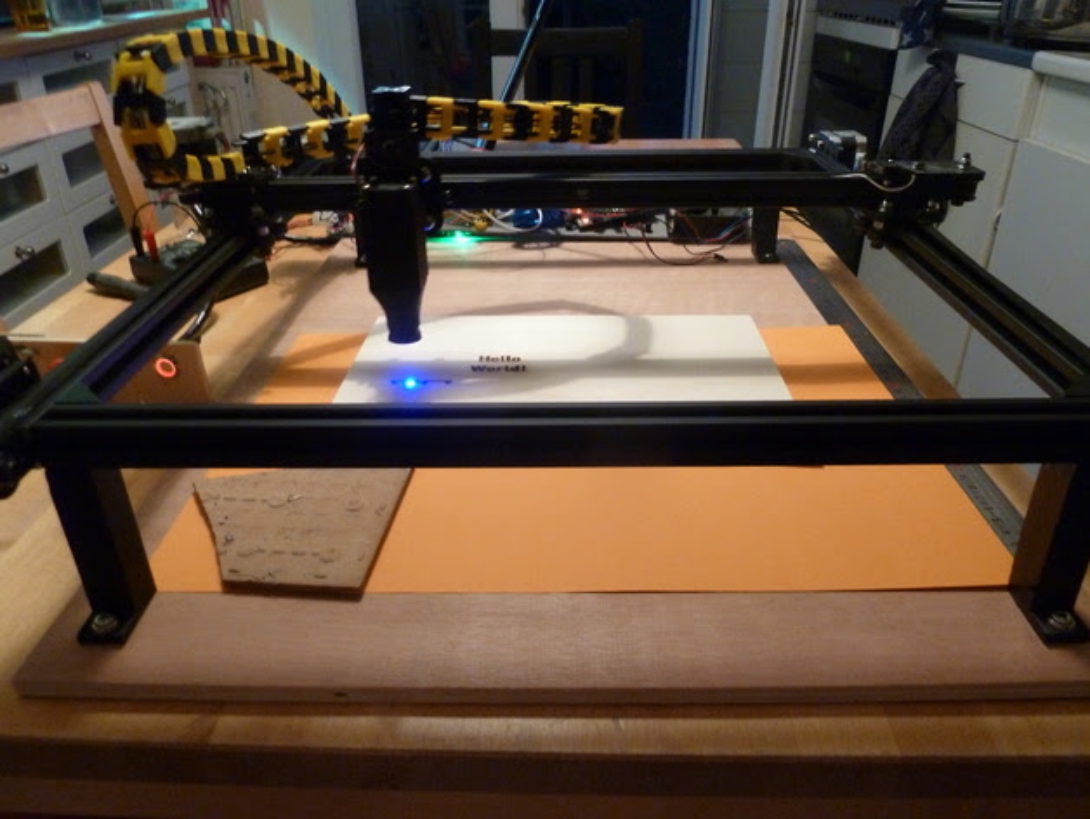

The laser cutter uses lasers to precisely cut or emboss material such as paper, leather, felt, etc. The accuracy that the laser cutter offers allows us to etch /cut intricate designs & shapes.

READ MORE

Wood-working tools: Using a collection of tools including power drills, saws, sanders, etc., students will work with plywood, wood, light metal, etc. to design and build furniture, objects, etc.

Electronics, including : Micro-controller boards (Arduino), Micro-processor boards (Raspberry Pi), Servos, motors, sensors, etc.